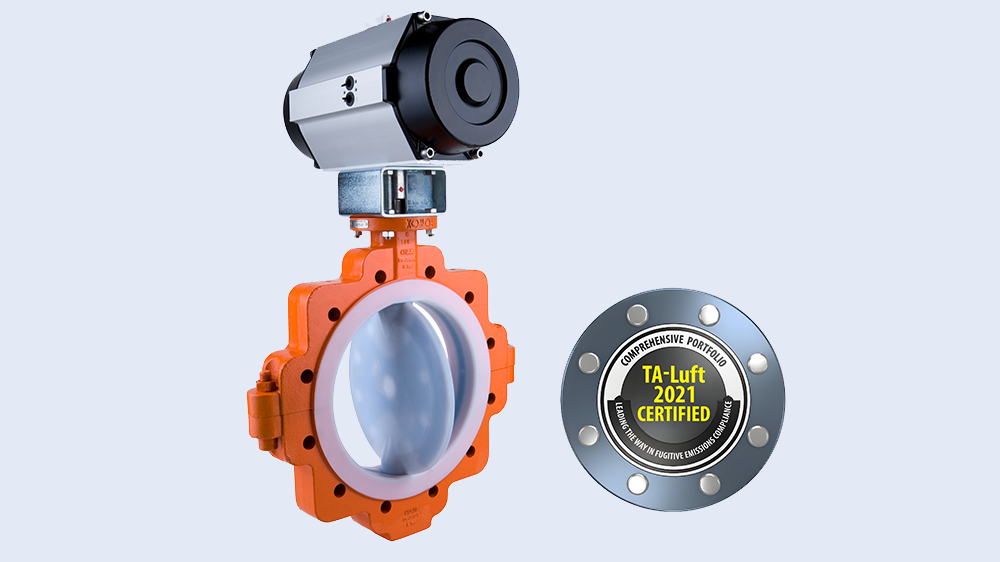

XOMOX® Lined Butterfly Valves Series XLD

The XOMOX® XLD Combines critical safety and performance features required for demanding service applications in chemical and industrial markets. Reconfigured stem packing and adjustment screw addition result in fugitive emission compliance and longer life.

Features And Benefits

Technical Details

Applications

Literature

Certificates

Videos

Features And Benefits

ISO 15848 AND TA-LUFT 2021 COMPLIANT

- After 4 thermal cycles and 2500 mechanical cycles less than 20PPM FUGITIVE EMISSIONS to atmosphere

BEST IN CLASS TORQUES

- Ease of use for operators and reduced initial investment of automation through INNOVATIVE BACKUP RING and STEM SEALING

ENHANCED IN LINE SEAL

- Valves are bubble tight on seat test and shell test after 10.000 open-close cycles

Technical Details

MATERIALS OF CONSTRUCTION

- Body and Disc in EN-JS1049 / ASTM A395 Ductile Iron, PFA / Teflon® Lined.

SIZE RANGE

- 2“ – 24“ DN50 – DN600

PRESSURE RATINGS

- Suitable for vacuum service (0.02 psi/1,33 hPa) Shut-off Pressure max. 150 psi/10 bar

TEMPERATURE RANGE

- -20° C to 200° C

- 253 K to 473 K

- -4° F to 392° F

Applications

- Chlorine

- Brine

- Benzene

- Bromine

- Sulfuric Acid

- Nitric Acid

- Hydrochloric Acid

- Phosphoric Acid

- Sea Water

Industries

- Chlor-Alkali

- Industrial Inorganic Chemicals

- Metal and Mining

- Pharmaceutical

- Nitrogen and Phosphatic Fertilizers

- Petroleum Refining

Literature

Flyer

XOMOX® Lined Butterfly Valves Series XLD – EN

XOMOX® Lined Butterfly Valves Series XLD – DE

Brochure

XOMOX® Lined Butterfly Valves Series XLD – EN

XOMOX® Lined Butterfly Valves Series XLD – DE

Manual

XOMOX® Lined Butterfly Valves Series XLD – EN

XOMOX® Lined Butterfly Valves Series XLD – DE