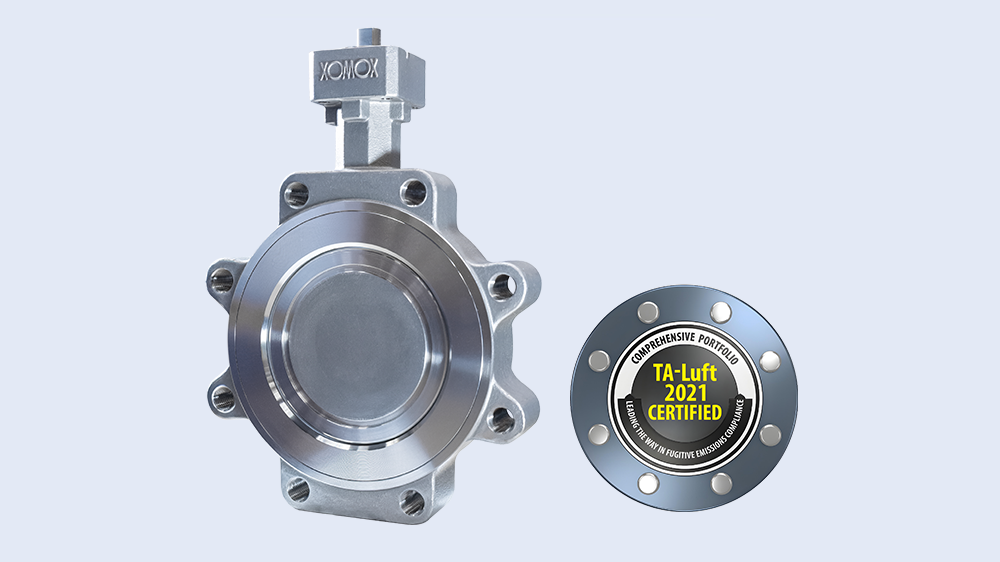

XOMOX® High Performance Butterfly ValvesType 800ISO

For more than 60 years, XOMOX® has delivered low‑maintenance, reliable valve solutions for chemical and petrochemical applications. The HPBV series raises the bar: thanks to its unique seat design, it achieves one million cycles while maintaining full operational integrity. Engineered for on/off and throttling/control applications, the HPBV offers maximum flexibility without the need for special modifications—ready to perform straight from stock across a wide range of processes. With bi‑directional dead‑end capability, extensive material options, and compliance with TA‑Luft 2021, ISO 15848‑1, API standards, and more, the HPBV ensures exceptional safety, durability, and performance—even at temperatures up to 550°C (1022°F).

Features And Benefits

-

ENDURANCE CHAMPION

Achieving ONE MILLION CYCLES while remaining fully operational thanks to our unique seat design that is not subject to the stress inducing axial flexion often seen in other valves of this type.

-

ULTIMATE FLEXIBILITY

Usable in ON/OFF or THROTTLING/CONTROL APPLICATIONS with no need for a special design or modifications. You can use a XOMOX® HPBV right out of your stock in multiple different applications without concern.

-

BI-DIRECTIONAL GUARDIAN

Suitable for BI-DIRECTIONAL DEAD-END SERVICE, even under full differential pressure – also available with a SMOOTH SEAT RETAINER RING.

Technical Details

MATERIALS OF CONSTRUCTION

- Standard: 1.0619, 1.4408; A216 Gr. WCB, A351 Gr. CF8M

- Optional materials available upon request including but not limited to Duplex, Superduplex, LCC/LCB, WC6, CF3M, Monel®, Inconel®, Hastelloy®, Alloy 20; 1.4469, 1.7357, 1.4409, 2.4460, 1.4539

SIZE RANGE

- Standard: DN 80 to DN 600 or 3” to 24”

- Optional Series 800: up to DN 2600 or 102”

PRESSURE RANGE

- Standard: PN 10, 16, 25, 40; ASME Class 150 & 300#

- Optional Series 800: up to PN 100 or 600#

- JIS, BS, API and other pressure classes on request

BODY CONFIGURATIONS

- Wafer & LUG acc. to DIN EN 558 (R16, R20, R25) & API 609

TEMPERATURE RANGE

- PTFE / RPTFE: -70°C to +232°C; -94°F to 450°F

- Metal-PEEK: -70°C to +260°C; -94°F to 500°F

- Fire-Safe (Metal/PTFE): -70°C to +300°C; -94°F to 572°F

- Metal/Graphite: -70°C to +550°C; -94°F to 1022°F

- Cryogenic (Metal-PCTFE): -196°C to +50°C; -321°F to 122°F

SPECIAL OPTIONS

- Fire-Safe

- Leakage Detection

- Primary stem seal

- Oil-free/Grease-free (various designs as per customer request)

- Oxygen application

- Chlorine and phosgene applications

- Smooth seat retainer

- Cryogenic design

- Heating jackets

Applications

Industrial branches:

- Chemical and petrochemical industry

- Oil and gas

- Air separation

- Chlorine liquefaction

- Power generation

- Energy

- Offshore platforms

- Pulp & paper

- Desalination

- Steam

- Corn processing

- HVAC

- Maritime vessels

Processes:

- Various chemicals

- Hot gases

- Chlorine gas

- Methanol

- Propane

- Liquid nitrogen

- Oxygen

- Carbon monoxide & carbon dioxide

- Sewage

- Recausticizing

- White water

- River water

- Cooked starch

- Scrubber effluent

- Fly and bottom ash

- Gasoline

- Tail gases

- Off gases

- Sour gas

- Sea water

Literature

Flyer

XOMOX® High Performance Butterfly Valves 800/800ISO – EN

XOMOX® High Performance Butterfly Valves 800/800ISO – DE

Brochure

XOMOX® High Performance Butterfly Valves 800ISO – EN

XOMOX® High Performance Butterfly Valves 800ISO – DE

Datasheet

XOMOX® High Performance Butterfly Valves 800/800ISO – EN

XOMOX® High Performance Butterfly Valves 800/800ISO – DE

Manual

Certificates

Standard Features And Compliance

- TA-Luft 2021 compliance or acc. to VDI 2440

- ISO 15848-1: 2017, Class BH, level CO3 standard, SSA0

- EPA Method 21 (Fugitive Emissions Compliance)

- API 609 and ASME B16.34; EN 12016 valve design standard

- Zero leakage as per API 598; EN12266 leakage rate A

- Fire-Safe acc. to API 607 and EN ISO 10497:2000

- Quality certification as per ISO 9001

- CE-marking according to DGRL 2014/68/EU & PED

- ISO 5211 actuator mounting bracket

- SIL 2 and 3

- API 641

- CRN (Canada) certified

- TSG (China) certified

- EAC (Russia) certified