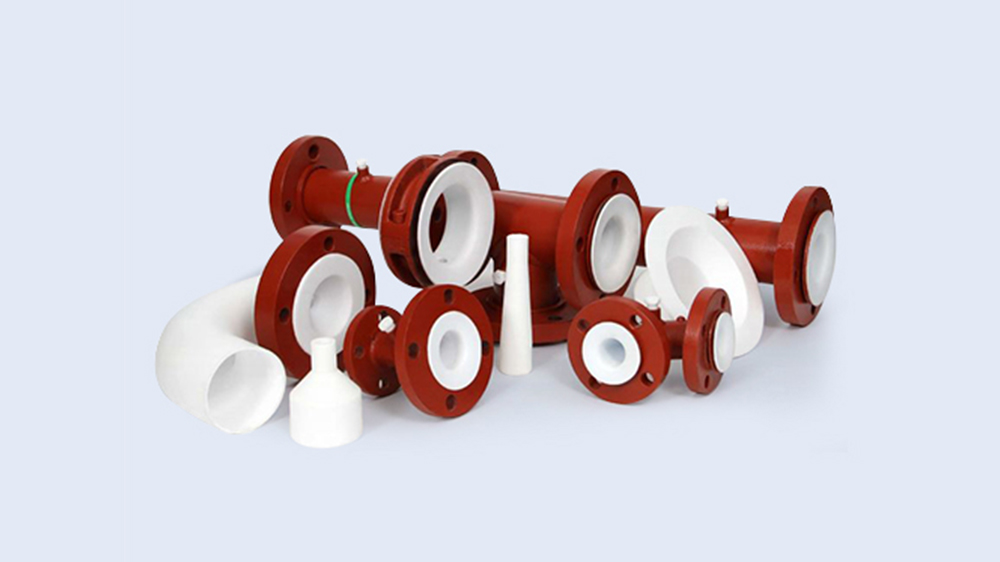

RESISTOFLEX® ATL

Resistoflex® ATL was designed specifically to address the challenges of handling severe service applications. It has been proven to reduce permeation rates by up to 60% and features a full vacuum rating up to 450°F (232°C). As such, ATL Lined Pipes and Fittings are an economical choice compared to Exotic Alloys or Glass Lining.

Features And Benefits

Optimized PTFE liner

Resistoflex®ATL PTFE liners are produced from carefully formulated resins and proprietary processing and lining techniques. The result is a molded PTFE liner that provides optimal crystallinity and strength. ATL PTFE liners provide the best permeation resistance in the industry.

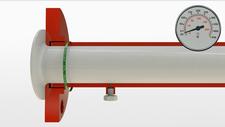

Enhanced venting system

Resistoflex®ATL PTFE pipe and fittings are designed to minimize any potential permeation attack of the housing by use of an advanced venting system that eliminates blockage and corrosion at the vent hole.

Highly chemical and temperature

Resistant paint system Resistoflex®ATL PTFE pipe and fittings are double coated with a highly chemical and temperature resistant paint. This paint is rated to 450°F (232°C) and can be used under insulation.

Technical Details

DESIGN FEATURES

- ATL Lined Pipes & Fittings

MATERIALS OF CONSTRUCTION

- Carbon Steel, Cast Steel & Ductile Iron

- Stainless Steel & High Alloys

- Low temperature Carbon Steel

SIZE RANGE

- 1″ to 12″ / DN 25 – DN 300

PRESSURE RATINGS

- Class 150 & 300 / PN 10 & 25

TEMPERATURE RANGE

- up to 450°F / 232°C

Applications

Halogenated Acids & Chlorinated Organics

- Chlor-Alkali / VCM

- Silicones

- Chlorofluorocarbons: Refrigerants/Cooling Systems

- Polysilicon: High-Purity for Solar Cells

- Polyurethanes: TDI-MDI

- Brominated Compounds: Fire Retardants

- Halogenated Butyl Rubber

- Agricultural Chemicals: Pesticides and Weed Killer

Certificates

- Certified to ISO 9001

- PED/CE Annex III Module H

- ASTM F1545-15a Certified Test Reports

- Fully Traceable MTRs to BS EN10204:2004 Type 3.1