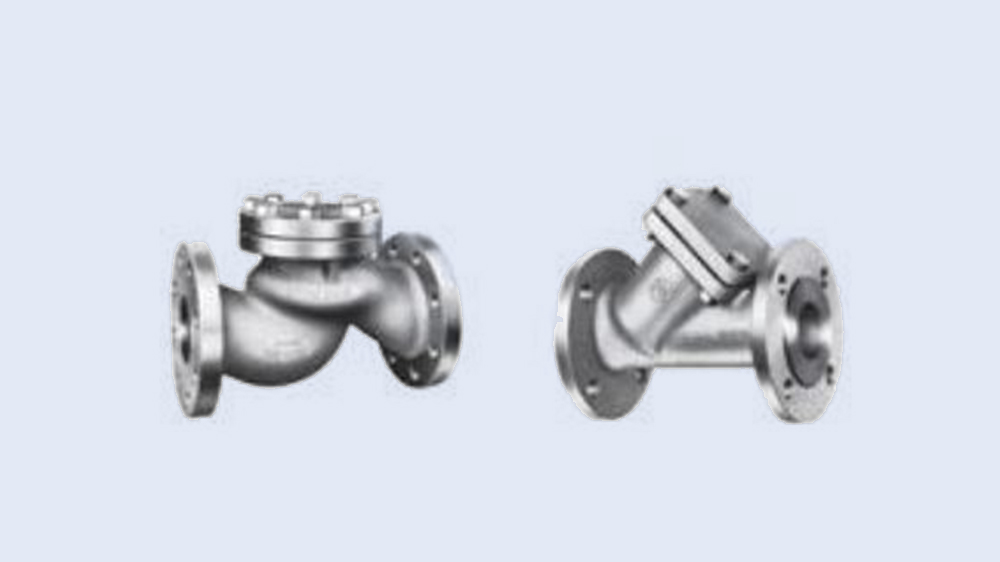

KROMBACH® Check Valves

KROMBACH® Check Valves in straight-through and Y-pattern design for industrial and chemical process application. The body and disc seat rings in stainless steel allows a horizontal and vertical process installations due to integrated spring-load design. Highest vertical integration inside Crane® ensures highest industrial quality and matching customized specifications over entire size range.

Features And Benefits

Technical Details

Applications

Literature

Certificates

Videos

Features And Benefits

- Face to face dimensions acc. to DIN EN 558-1

- Flanges on request according other standards (BS, ANSI etc.) or with butt-weld ends or socket-weld ends

- Check valve design allows horizontal and verticall installation.

- Other nominal sizes, extended material availability and further customization on request.

Technical Details

SIZE RANGE

- DN 15 to DN 200

PRESSURE RATINGS

- PN 10 to PN 160

EMPERATURE RANGE

- 20°C to 400°C

BODY CONFIGURATION

- Straight through and Y-pattern lift check valves

- Flanges made according to other standards (BS, ANSI etc.) butt-weld ends or socket-weld ends

SPECIAL OPTIONS

- Other nominal sizes, materials and further special designs on request.

Applications

Industrial and chemical applications, chemical processing and fluid handling process water applications, for liquid media in corrosive and severe applications.

Certificates

- DIN EN 558-1 series 1 (PN 10 – PN 40)

- DIN EN 558-1 series 2 (PN 63 – PN 160)

- TA Luft

- Atex Directive 94/9/EG, DIN EN 13463-1; DN 1127-1