CRANE® CRYOGENICS’s Innovation in Cryogenic Fluid Transfer:

The Pivotal Role of CRANE® CRYOGENICS Bayonets

Cryogenic fluids, essential in diverse fields ranging from space exploration to medical science, pose unique challenges demanding specialized equipment for their handling and transfer. In cryogenics, where temperatures go below -150°C (-238°F), essential engineering is necessary to ensure these fluids’ safe and efficient handling. Within this landscape, bayonets emerge as critical components, ensuring the integrity and efficiency of cryogenic systems.

CRANE® CRYOGENICS, a leader in cryogenic technology, has pioneered advanced male and female bayonets that redefine the boundaries of fluid transfer performance and reliability. Let’s explore the intricacies of cryogenic fluid transfer and understand the role of bayonets in ensuring efficient and safe transfer.

Cryogenics studies materials at extremely low temperatures, typically below 150°C (238 °F). At these frigid temperatures, materials exhibit distinct properties, necessitating specialized equipment for handling and transferring. Cryogenic fluids, such as liquid hydrogen, nitrogen, oxygen, and helium, possess unique characteristics: they are exceptionally cold, highly reactive, and prone to rapid expansion upon warming.

Challenges in Cryogenic Engineering

Engineering for very low temperatures presents distinct challenges. Thermal insulation, material selection for low-temperature durability, and designing systems that accommodate the rapid thermal expansion and contraction of materials are essential considerations.

Bayonets: Guardians of Cryogenic Systems

Bayonets are specialized fittings crucial for the transfer of cryogenic fluids. They are essential for cryogenic systems, ensuring:

- Secure Connections: They provide robust connections between piping sections, enabling the safe and efficient transfer of cryogenic liquids and gases.

- Leak Prevention: Impeccable sealing technology minimizes leaks, reducing environmental impact and ensuring operational safety.

- Thermal Efficiency: Their design minimizes heat transfer, preserving the cryogenic state of the fluids and maximizing system efficiency.

Design Considerations for Cryogenic Bayonets

Designing bayonets for cryogenic applications requires careful consideration. The following are some of the critical factors that must be considered:

- Material Selection: Materials must withstand extreme cold, maintain strength and flexibility, and resist wear and corrosion. Stainless steel is an essential choice for cryogenic bayonets due to its durability and resistance to corrosion.

- Sealing Technology: Innovative seals must endure extreme temperature variations and maintain a leak-proof barrier under diverse pressure conditions.

- Thermal Insulation: Advanced materials and design features minimize heat leaks, preserving the cryogenic state of the fluids.

- Ergonomic Design: Bayonets should be easy and safe to operate in cryogenic environments, even when wearing protective gear.

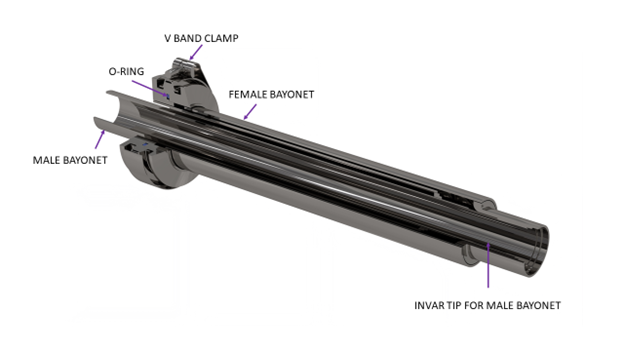

Male and Female Bayonets

Male and female bayonets are the two types used in cryogenic applications. A detailed comparison of the two types highlights their distinctive features and functionalities.

Male Bayonets:

- Protruding design with external seals

- Withstands insertion forces and dynamic fluid pressures

- Typically thicker walls

- Requires precise alignment for insertion

Female Bayonets:

- Internal cavity with internal seals

- Prioritizes internal temperature stability

- Maintains consistent sealing under varying pressure conditions

- Provides secure containment for the male bayonets

CRANE® CRYOGENICS’s Bayonets

CRANE® CRYOGENICS’s bayonets are designed to provide optimal performance and reliability in cryogenic applications. Some of the advanced details of our bayonet design include:

- Utilizing cryogenic-grade stainless steel for optimal low-temperature performance.

- High-performance seals that maintain exceptional sealing capabilities across a wide temperature range.

- Internal design minimizes turbulence and ensures consistent fluid flow, maximizing efficiency.

- Features facilitate easy and safe operation in cryogenic environments.

Comparison between Bayonets and Field Joints

Field joints are an alternative to bayonet couplings, offering a different approach to joint design. While both types of couplings fulfill similar functions, they are each suited to distinct applications based on their design characteristics.

| Feature | Feature Bayonet Couplings | Feature Bayonet Couplings |

|---|---|---|

| Design | Mechanical joint allowing quick assembly and disassembly | Welded coupling, wrapped with insulation and evacuated |

| Ease of Assembly | Can be easily dismantled and assembled | Requires welding and insulation work |

| Heat Leak | Designed to maintain a low heat leak at the joint | Super-insulation and evacuation to standard vacuum level to minimize heat leak |

| Sealing | Uses O-rings and close tolerance for sealing | Utilizes welded coupling for sealing |

| Thermal Isolation | Long design for thermal isolation between room temperature and cold piping | Insulation and vacuum provide thermal isolation |

| Use Cases | Useful for lines that need frequent disassembly | Suitable for permanent connections |

CRANE® CRYOGENICS offers options for both bayonets and field joints to its customers.

Conclusion

Cryogenic bayonets are critical components that ensure cryogenic fluids’ safe and efficient transfer in diverse applications. Bayonet design must consider the unique challenges posed by very low temperatures and design features that maximize efficiency, minimize heat transfer, and prevent leaks. CRANE® CRYOGENICS’s advanced bayonet design sets the bar for cryogenic transfer performance and reliability, pushing the boundaries of cryogenic technology.

Discover More Here

CRANE® CRYOGENICS offers Pipe Valves and Fittings (PVF) solutions for the production, transportation, transfer, and storage of Hydrogen, backed by decades of field experience in severe service applications.

CRANE CRANE® CRYOGENICS – CRANE ChemPharma & Energy (cranecpe.com)