CRANE® CRYOGENIC PRODUCTS

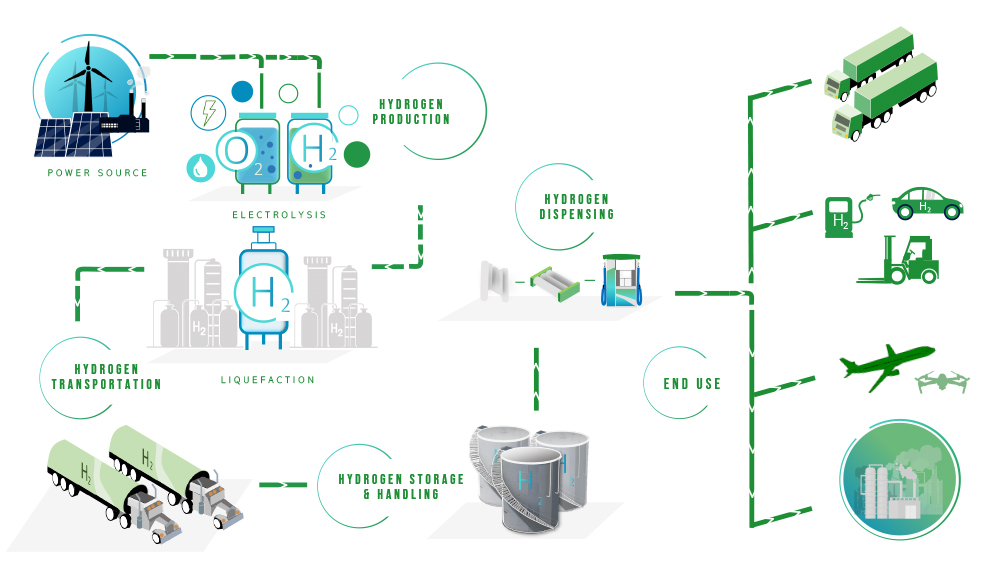

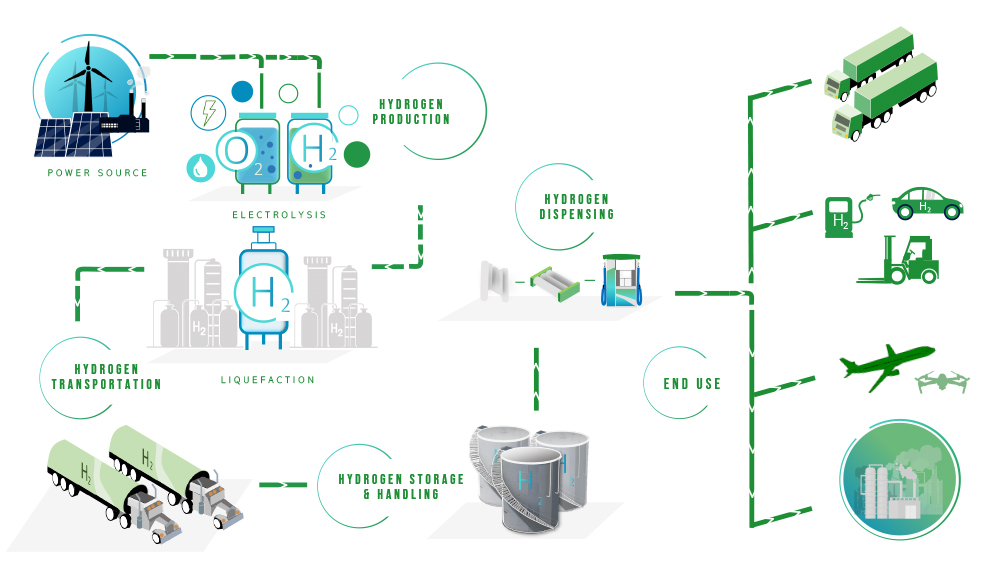

Hydrogen and other cryogenic energy sources are gaining popularity as clean, abundant and renewable alternatives to fossil fuels. However, these energy sources also pose some technical challenges, such as the need for efficient and safe production, liquefaction, transportation, transfer and storage of cryogenic fluids.

To address these challenges, the cryogenic industry requires state-of-the-art PVF (Pipe Valves and Fittings) components that can handle the extreme conditions of low temperatures and high pressures.

CRANE® CRYOGENIC PRODUCTS are a trusted provider of PVF solutions for the cryogenic industry, with a focus on hydrogen and other cryogenic fluids, such as nitrogen, argon, oxygen etc. Crane® has decades of field experience in severe service applications, and offers a wide range of products and services to meet the needs of customers in the value chain.

CRANE® CRYOGENIC PRODUCTS cryogenic solutions include:

Production: CRANE® CRYOGENIC PRODUCTS offers high-performance valves, fittings and accessories for cryogenic production plants, such as steam methane reforming, electrolysis and thermochemical processes. These components are designed to withstand high temperatures, pressures and corrosive environments.

Liquefaction: CRANE® CRYOGENIC PRODUCTS provide reliable and efficient valves, pumps and heat exchangers for cryogenic liquefaction plants, which can reduce the volume of cryogenic fluids by hundreds or thousands of times. These components are designed to prevent leakage, cavitation and thermal shock.

Transportation: CRANE® CRYOGENIC PRODUCTS supplies vacuum jacketed piping (VJP), valves and fittings for transporting cryogenic fluids by road, rail or ship. VJP is a double-walled pipe system that minimizes heat transfer and evaporation losses. These components are designed to ensure flexibility, durability and safety.

Transfer: CRANE® CRYOGENIC PRODUCTS delivers safe and easy-to-use fill and withdrawal assemblies, valves and hoses for transferring cryogenic fluids from tanks to vehicles or dispensers. These components are designed to ensure compatibility, accuracy and reliability.

Storage: CRANE® CRYOGENIC PRODUCTS designs and manufactures vacuum jacketed storage tanks, valves and accessories for storing cryogenic fluids at low temperatures and pressures. These components are designed to ensure optimal thermal performance, security and longevity.

Further Reading:

How to Save Energy and Reduce Heat Loss with CRANE® CRYOGENIC PRODUCTS Vacuum Jacketed Pipes

|   |

Please watch our PVF Solutions for Hydrogen – Keeping Cryogenics Cool VideoCLICK HERE | CRANE® CRYOGENIC PRODUCTS Bellows Seal Globe Valve (BSGV)CLICK HERE |