CRANE® CRYOGENIC PRODUCTS Vacuum Jacketed Rigid Piping

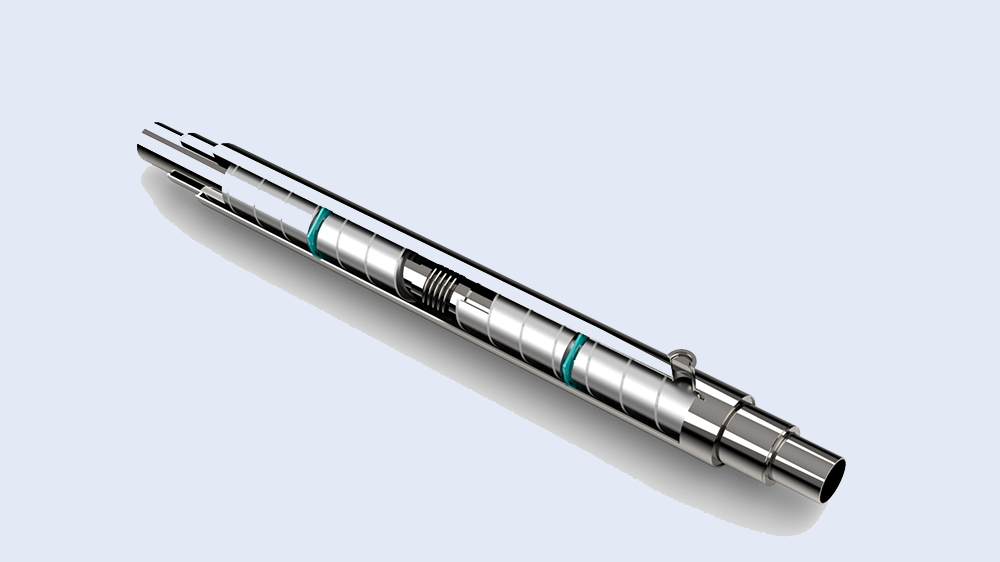

CRANE® CRYOGENIC PRODUCTS Vacuum Jacketed Rigid Piping (VJP) is a double-walled piping system with a vacuum space between the inner and outer pipes. This vacuum space acts as a thermal barrier that reduces heat transfer and prevents product boil-off, minimizing product loss and ensuring safety and quality. VJP offers a number of significant advantages over conventional piping systems for liquid cryogenic media.

Features And Benefits

Technical Details

Applications

Literature

Certificates

Videos

Features And Benefits

- Technological Breakthroughs: Using IT innovations to achieve best-in-class quote turnaround times for our products.

- Lead Time: Market leading lead times thanks to our state-of-the-art manufacturing processes.

- Reduced Heat Transfer: Minimized product loss with Multi-layer insulation and end connections such as bayonets and field joints.

Technical Details

PRODUCT CONFIGURATION:

- Type: Stainless Steel Vacuum Jacketed Pipe

- Body Styles: 300 Series Stainless Steel

- End Connections: Bayonet, Field Joint, Mechanical Fitting

- Pressure: Upto 150 PSIG

- Inner Pipe Size: 1/2″, 1”, 1-1/2”, 2”, 3”, and 4” NPS

DESIGN FEATURE:

- Fugitive Emission: Helium mass spec to 1×10^-9 cm^3/s and Pneumatic Pressure test to 1.1x the design pressure.

- Outgassing Getter, Molecular Sieve & Multi-Layer Insulation for Static Vacuum

- ASME B31.3 Certification

- Pressure Drop, Heat Leak, and Thermal Contraction of the System

- Internal G-10 Supports and Outer Pipe Supports

DESIGN STANDARD:

- ASME B31.12: Hydrogen Piping & Pipeline

- ASME B31.3: Process Piping

- CGA G-4.15: Vacuum-Jacketed Piping in Liquid Oxygen Service

- CGA G-5.6 – Hydrogen Pipeline Systems

- AWS 2.4 Standard symbols for welding, brazing and non-destructive examination

- AWS B2.1, ISO 15607, EN 1011-1: Specification for welding procedure and performance qualification

- AWS D10.18 Pipe welding (stainless steel)

- ASME B16.5: Pipe Flanges and Flanged Fittings

- ASME B16.9 – Factory made Wrought & fabricated butt welding fittings

- ASME B36.19M : Stainless Steel Pipe

- ASME BPVC Section IX: Welding and Brazing Qualifications

TESTING STANDARD:

- ASME B31.12: Hydrogen Piping & Pipeline

- ASME B31.3: Process Piping

- AWS B1.10 & ISO 17035: Guide for nondestructive examination of welds

- ASME BPVC Section V – Nondestructive Examination

Applications

- Liquefaction

- Storage

- Transport and distribution of Cryogenic Hydrogen

- Nitrogen Oxygen

- Helium and other inert gases