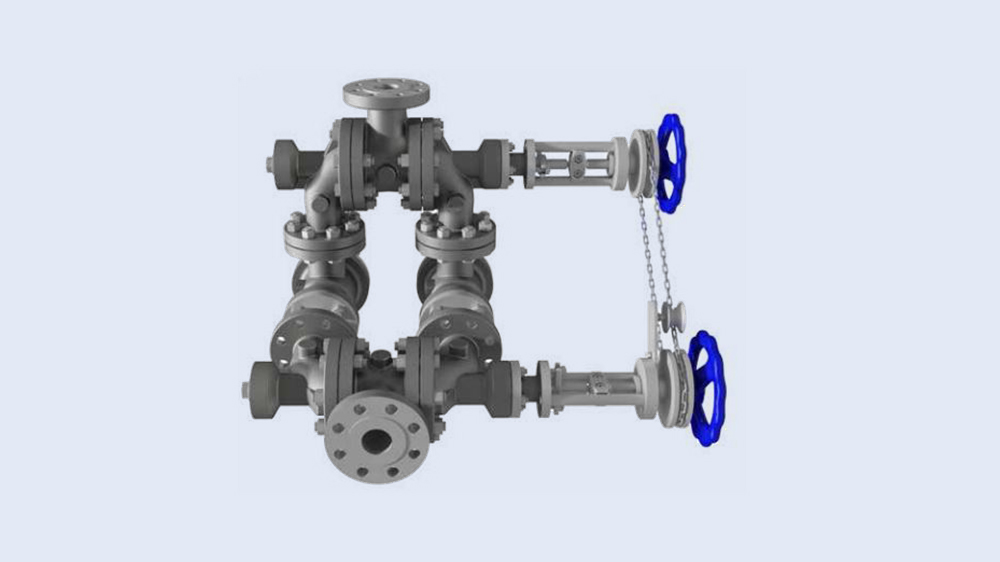

WTA® Change Over Valves Types 11.7, 11.8, 11.75 & 11.85

WTA® Change Over Valves are used to connect two safety valves to a pressure system using one pipe point. Here, one safety valve is in operation and one safety valve is on stand-by. The stand-by valve can be removed during ongoing operation for service, while protection of the pressure system against inadmissible pressures is maintained. The use of change over valves allows essential maintenance work to be carried out on a safety valve, without interruption of the plant operation. This is realized by simply switching over to the relevant stand by safety valve, thus protecting the plant against excessive overpressure.

Features And Benefits

Technical Details

Applications

Literature

Certificates

Videos

Features And Benefits

- The three-way change over valves are ideal for environments where continuous plant operation is essential

- Extremely low pressure loss coefficients (zeta values from 0,60 to 1,05) permit optimal flow rates to fulfill the legal requirement of less than 3% pressure loss

- Two designs are available for use in chemical, petrochemical, pharmaceutical or refining services: one with packing sealing (11.7/11.75) and one with bellows sealing (11.8/11.85)

Technical Details

MATERIALS OF CONSTRUCTION

- Carbon steel 1.0619 / WCB / WCC

- Stainless steel 1.4408 / CF8M

- Low temperature carbon steel 1.6220 / LCB / LCC

- Special materials on request

SIZE RANGE

- DN15-400 / NPS 1/2”-16”

- Other sizes are available upon request

- End Connections available according to DIN and ASME standards

- Flange design in accordance with EN 1092-1 and ASME B 16.5

PRESSURE RATINGS

- PN10-400 / Class 150-2500

TEMPERATURE RANGE

- Carbon Steel: 14°F to 752°F

- Stainless Steel: 328°F to 752°F

- Low Temp. Carbon Steel: -40°F to 572°F

Applications

- Petrochemical industry

- Oil and gas industry

- Technical gases

- Chemical

- Refrigeration

- Pharmaceutical industry

Certificates

- Permissible working pressure according EN 1092 part 1 and ASME B16.34-2009

- Inspection and testing per EN 12266 and API 598

- Design in accordance with TA-Luft (11.8/11.85)

- TR certificate of conformity