Cryogenics, defined by its focus on creating and managing environments at extremely low temperatures, has been a source of fascination and innovation for many years. It is integral to a variety of industries, ranging from aerospace to energy storage, and has a multitude of applications. One of the most prominent and widely used cryogenic fluids is liquid hydrogen, which stands out due to its high energy density and potential as a clean, sustainable energy carrier. In this article, we delve deep into the world of cryogenics, exploring the production and properties of liquid hydrogen, the challenges associated with its storage and transportation, and how CRANE® CRYOGENIC PRODUCTS Vacuum Jacketed Pipes (VJP) offer an unparalleled solution for reducing heat loss and saving energy in cryogenic systems.

Liquid hydrogen is produced from its gaseous form through a process called liquefaction. This involves compressing and cooling the gas until it condenses into a liquid state, which is achieved using methods such as the Claude and Linde-Hampson systems. These methods, although different in their approach, share the common goal of producing liquid hydrogen at a temperature of -252.87°C (-423.17°F). Understanding the properties and behaviors of liquid hydrogen is crucial for its safe and efficient storage, transportation, and use.

The unique properties of cryogenic fluids like liquid hydrogen necessitate specialized storage solutions and transportation methods. Dewars, which are double-walled, vacuum-insulated tanks, are commonly used for storage, with the vacuum space providing an effective thermal barrier. When it comes to transportation and the transfer of cryogenic fluids between dewars, both rigid and flexible transfer lines are employed. The choice between these two options depends on a variety of factors, including the distance over which the fluid needs to be transferred and the specific requirements of the application.

The field of cryogenics is rapidly expanding, with innovations and advancements being made regularly. Liquid hydrogen is particularly noteworthy in this context due to its potential to revolutionize how we produce, store, and transport energy. As we continue to seek out cleaner and more efficient energy solutions, cryogenics is poised to play a central role in the development of a hydrogen economy, with the potential to significantly reduce our reliance on fossil fuels and lower our greenhouse gas emissions.

Despite its potential, the storage and transportation of cryogenic fluids are not without challenges. These include boil-off losses, the risks associated with handling flammable and volatile substances, and issues related to material compatibility. Many materials, including metals, composites, polymers, and ceramics, are used in cryogenic applications, each with specific advantages and drawbacks. Selecting the suitable material for a given application is a critical step in ensuring the safety and efficiency of a cryogenic system.

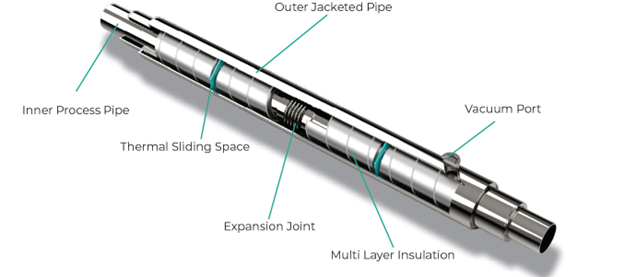

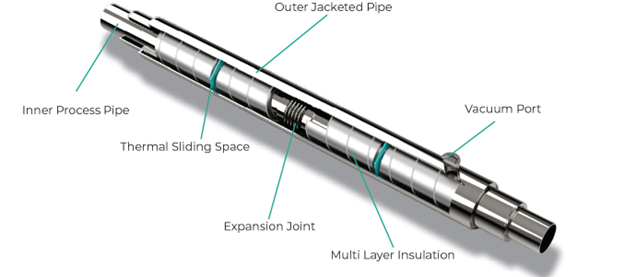

In cryogenic systems, managing and minimizing heat transfer is paramount. The goal is to maintain the extremely low temperatures required for cryogenic fluids and to prevent product loss due to boil-off. Vacuum Jacketed Pipes (VJP) play a crucial role in achieving this, providing superior insulation and ensuring the longevity and efficiency of cryogenic systems.

CRANE® CRYOGENIC PRODUCTS Vacuum Jacketed Pipes

CRANE® CRYOGENIC PRODUCTS VJPs are the best in the market, with unmatched quality, durability, and flexibility. They can handle different kinds of cryogenic fluids and applications with no leaks, no corrosion, and minimal heat loss and energy consumption.

CRANE® CRYOGENIC PRODUCTS has a range of vacuum-jacketed piping solutions for cryogenic applications, providing specialized and efficient solutions for the industry:

• CRANE® CRYOGENIC PRODUCTS Vacuum jacketed rigid piping is a double-walled pipe with a vacuum that prevents heat transfer and product boil-off. It transfers cryogenic liquids, such as hydrogen, nitrogen, and oxygen.

• CRANE® CRYOGENIC PRODUCTS Vacuum jacketed flexible piping is a vacuum-insulated pipe with a flexible outer jacket. It transfers cryogenic liquids from a bulk storage vessel to use points in process plant installations.

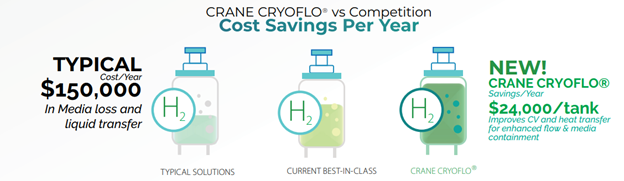

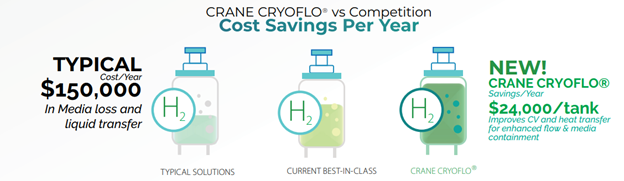

• CRANE® CRYOGENIC PRODUCTS manifolds are custom-made for cryogenic liquid transfer with high-quality components, improved flow and heat control, and easy connections that fit all storage tank and trailer layouts. They use the CV Bellows Seal Globe Valve for better performance and reliability.

CRANE® CRYOGENIC PRODUCTS VJPs are adaptable and can be tailored to suit the specific needs of different cryogenic fluids and applications. The company adds unique features to deal with the challenges of cryogenic systems. CRANE® CRYOGENIC PRODUCTS follow quality and safety standards to ensure their VJPs are the best in performance, reliability, and security. This makes the company a leader in the field, offering advanced cryogenic solutions to the world.

CRANE® CRYOGENIC PRODUCTS VJPs save energy and reduce heat loss when used in cryogenic systems. This improves efficiency, quality, and sustainability, making cryogenic systems more reliable and effective. Cryoflo’s VJPs are used in various industries, showing their versatility and efficiency in transferring cryogenic fluids across different sectors. From LNG and petrochemicals to food and beverage, these pipes are essential for various applications. To get the most out of VJPs, they must be installed, inspected, and maintained properly. This ensures the best performance, longevity, and safety, avoiding risks and inefficiencies and ensuring the cryogenic system works well.

Cryogenics is a field of immense potential, and it plays a critical role in the quest for cleaner and more efficient energy solutions. CRANE® CRYOGENIC PRODUCTS vacuum-jacketed pipes and other cryogenic solutions are at the forefront of this field, providing energy-efficient, safe, and reliable options for storing and transporting cryogenic fluids. As the world continues to move towards cleaner energy alternatives, the innovations and advancements made by companies like CRANE® CRYOGENIC PRODUCTS will be instrumental in shaping the future of energy production, storage, and transportation. With a focus on quality, safety, and innovation, CRANE® CRYOGENIC PRODUCTS are helping to lead the way in developing advanced cryogenic solutions, contributing to a more sustainable and efficient energy future.

CRANE® CRYOGENIC PRODUCTS Hydrogen PVF Pipe, Valves and Fittings (cranecpe.com)